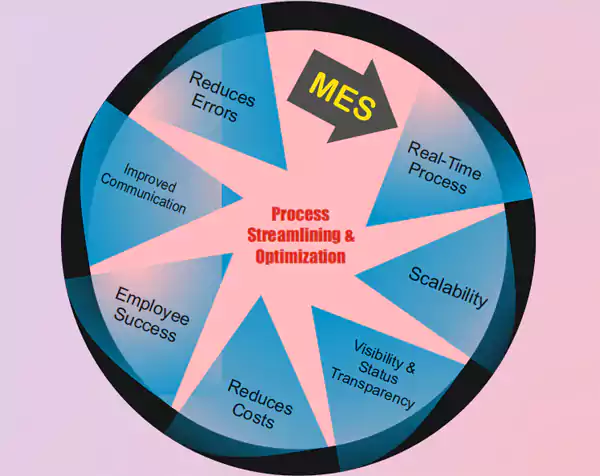

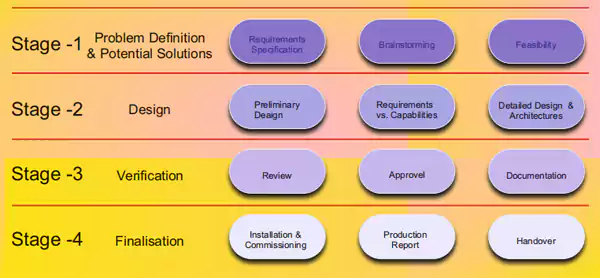

PRG Automation provides integrated design of automated systems. Our expertise covers the full spectrum of disciplines required to develop the necessary equipment for clients' applications, including mechanical, electrical and instrumentation designs, PLC, DCS, HMI and movement control systems programming, as well as SCADA and MES applications.

More specifically, PRG Automation provides engineering, design, and troubleshooting services for systems to ensure quality and proper integration of system components, motor control circuits, power supplies, PLCs and mechanized systems. We are on the lookout for new technologies to ensure that we apply contemporary solutions that will provide greater longevity. Our mechatronics experts can design complete production equipment tailored to clients' needs by combining several disciplines, such as mechanical and electrical design, as well as any other discipline required for its implementation.