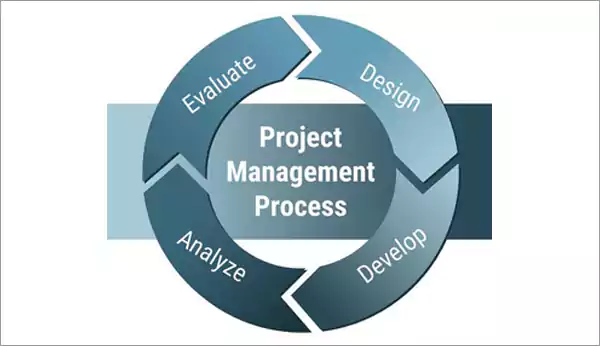

Project management is one of the most important factors or a successful project, and PRG Automation adheres to the recognized principles in this field. We promote the use of project management milestones: Definition, Design, Development, Deployment, Direction and Documentation. Our approach, based on the WBS (Work Breakdown Structure), ensures monitoring that focuses on all of the levels while the project is being carried out, eliminating many problems that might interfere with the schedule.

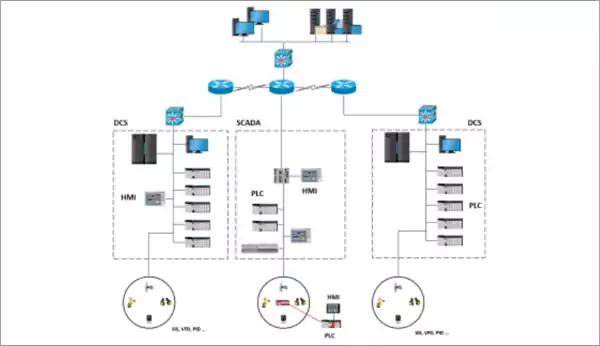

With so many years of experience in industrial automation, PRG Automation provides consulting services to solve expansion problems and the associated headaches.Our consulting teams can help clients identify and eliminate the operational restrictions that impact profitability, such as inefficiencies, obsolete, under-utilized, or unsuitable technologies, capacity bottlenecks, and manufacturing, planning and resource levelling problems, as well as a lack of strategic vision. With the help of PRG Automation, clients can turn problems into benefits for the company.

PRG Automation has machine safety integrated into its genetic code. All the machines it designs meet the appropriate safety standards. Thus, it is with the safety of workers in mind that we intervene in any application, whether designed by us or by third parties. Our advanced knowledge and our proven work methods ensure adequate protection and clear procedures. With clients cooperation, we are able to identify, measure, assess and monitor risks, and make the necessary adjustments in order to comply . All robotic projects at PRG Automation meet safety requirements under current laws and regulations. Thus, each application is reviewed by our machine-safety experts and a risk analysis is performed and validated. Safety is designed to maximize productivity while minimizing risks to employees and equipment.

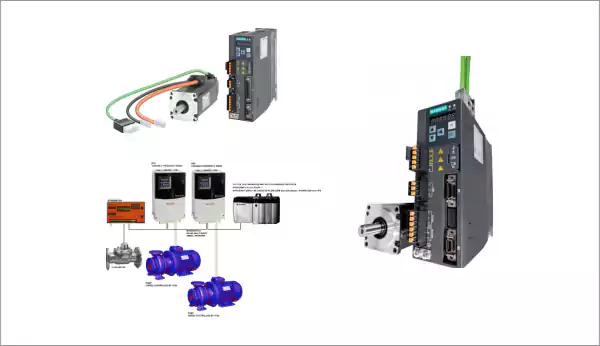

- Motion Technology Selection

- Safety Function Consideration

- VFD / Servo Parameterisation

- Integration with PLC & HMI

- Testing

- PLC modules with 1, 2 or 4 axis motion

- Network ready multi-axis controllers

- Interpolated (linear and circular) motion control

- Network ready indexer / drive combos

- Integrated drive and motor packages

- Easy setup and operation

- AC and DC powered microstepping drives

- NEMA frame sizes 23 to 42 stepper motor.

- Siemens / AB / Delta / Mitsubishi / ABB